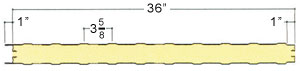

AD LOC 100 panels are used in both industrial and commercial applications. Their unsurpassed insulating capabilities and strength make them ideal for a broad range of uses in both hot and cold weather. The metal panels come in 36" widths allowing for quick installation – a crucial attribute given Western Canada's labour shortage. A hidden fastener panel is available for commercial applications. Embossing and a variety of colours are available as well.

If you're currently looking for steel roof panels or wall panels, contact us for details on how AD LOC 100 can meet your specific requirements.

Load Tables: 1.5" | 2" | 2.5" | 3" | 4"

ADLOC 100 Polyurethane Insulated Panels are composed of corrugated steel skin exterior with a Polyurethane foam core interior. The panels are manufactured in a 36” width with varying lengths and thicknesses of 1-1/2”, 2-1/2”, 3” and 4”. The panels are used for residential or commercial building construction.

Physical Ratings:

Individual ADLOC 100 panels have achieved the following mechanical ratings:

| Standard | Rating |

| ASTM E330 | Average Ultimate Transverse Load of 110.9 psf for panels measuring 3 ft x 8 ft Average Ultimate Transverse Load of 76.3 psf for panels measuring 3 ft x 8 ft |

ADLOC 100 panels measuring 3 ft wide and 1-1/2 in. thick with various lengths fastened every 12 in. o.c with #8 x ¾” Hex Head Tek and Polystyrene Butadiene Styrene sealant applied along the seams have achieved the following ratings:

| Standard | Performance Properties | Rating |

| ASTM E330 | Air Leakage | Maximum air infiltration and exfiltration of 0.001 cfm/ft2 at 6.3 psf pressure difference |

| ASTM E331 | Water Penetration | No water penetration at a rate of 5.0 US gal/ft2h and 6.3 psf for 15 minutes |

| AAMA 501.1 | Dynamic Pressure Water Penetration | No water penetration at a rate of 5.0 US gal/ft2h and 6.3 psf for 15 minutes |

Fire Ratings:

| Standard | Fire Performance | Rating |

| CAN/ULC S102 | Surface Burning Characteristics | Flame Spread Classification: 5 Smoke Developed Classification: 200 4 in. thick panel including the steel skins fastened every 12 in. with #8 x ¾” Hex Head Tek screws and Polystyrene Butadiene Styrene sealant running down the center of the panel. |

| CAN/ULC S127 | Flammability Characteristics | Flame Spread Rating: 425 4 in. Exposed Polyurethane Foam Core |

| CAN/ULC S101 | Wall Assembly Fire Resistance | 15-Minute Stay-in See design listing APP-FWPA 15-01 for assembly details |