Steel or structural insulated panels (SIPs) are building panels used in walls, floors and roofs. Their other applications include, residential and commercial buildings, freezer coolers, oil field applications, agricultural structures and more. Steel panels are made by sandwiching rigid foam plastic insulation between two structural metal skins.

SIPs provide many benefits, including the fact that they’re manufactured under factory-controlled conditions and engineered-stamped, guaranteeing their quality and making it possible to customize them to fit each customer’s needs. Most importantly, however, customers receive metal structures that are strong, cost-effective and energy efficient when they choose to use our SIPs. Let's take a look at some of the other benefits that these panels have to offer:

SIPs are Strong and Durable

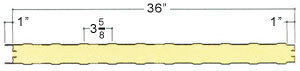

SIPs have a design that gives them the advantage when handling in-plane compressive load. The metal skin works like a flange, while the foam core acts as a web, which is comparable to how a steel I-Beam operates. Plus, Advanced Panel Products manufactures panels that are 24 or 26-gauge steel or aluminum and 32” or 36” wide. The panels can be used in several applications, including providing health grade panels for freezer coolers with Health Canada approval.

Are Easier and Faster to Install

Using SIPs allows for faster build times, specifically when it comes to residential and commercial structures. In fact, these SIPs can be installed 20 to 35 percent faster than other building systems. Our panels can be manufactured up to 32” long and extended with an ‘h’ channel for the next panel to sit in. This way, the height of a wall can be increased as needed.

SIPs can also be manufactured as “ready to install” components. So, when they arrive at a jobsite, there won’t be any need to insulate, frame or sheath stick-framed walls. Window openings can also be precut into panels without the need to install a separate header. Additionally, electrical chases are usually placed into the core of the panels, so the crew won’t need to drill through studs for wire installation.

SIPs are Eco-Friendly

Insulated panels are the eco-friendliest building systems on the market. SIP building envelopes are airtight and provide high levels of insulation. This means that the amount of energy used to cool or heat a building can be reduced by as much as 50 percent. Builders, homeowners and architects that use SIPs will be helping reduce greenhouse gases and promote a clean, ‘green’ environment.

Are Compatible with Other Systems

Steel insulated panels can sit on several types of foundation materials, such as blocks, insulated concrete forms and poured concrete. SIPs are also sized to be compatible with stick framing and to receive dimensional lumber. For example, a builder could easily build a SIP roof with stick walls or a conventional roof with SIP walls. Plus, SIPs are a great choice for builders that want to create a well- insulated building envelope for timber structures.

SIPs are Cost-Effective

Structural insulated panels help builders save money on labour and construction. For example, building tightness and whole wall R-values capable with SIPs allow ductwork to be minimized and HVAC systems to be downsized. Jobsite waste disposal and temporary heat during construction can also be reduced with the use of SIPs. The amount of energy used in a home is reduced, which can also help homeowners save on energy bills, increase their property values and qualify for energy efficient mortgages.

If you have questions about any of the SIPs products we provide at Advanced Panel Products, please contact us.